Fontys unlocks digital twins for SMEs with Digital Twin Academy

Digital twins are revolutionising the manufacturing industry. They make it possible to produce more efficiently and to offer better maintenance and service (also preventively). The technology is there, but the study of its application in the field is in full swing. Fontys University of Applied Sciences ICT participates has joined the international partnership Digital Twin Academy as a research partner. The aim of this joint project is to make the knowledge and applications of digital twins available to small and medium-sized enterprises (SMEs).

What are digital twins?

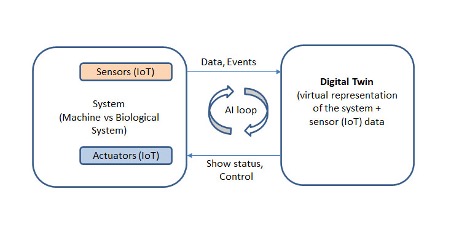

Simulations and virtual reality applications have been used for some time to design and maintain systems. Digital twins are the next step within the Smart Industry/Industry 4.0. Not only is a digital reproduction made; it can be linked to the physical object in real time. So if you change the physical object, the twin changes with it. Teade Punter, lector High Tech Embedded Software, who coordinates the project together with research coordinator Tom Langhorst on behalf of Fontys explains: "Many companies in the Brainport region are working on digital twins. There is a need in the machine industry for a representation that makes it possible for several people to work on a product at the same time, for example. What we are investigating is how you can develop and apply such a digital twin as smartly as possible. Twinning is an investment, so how can you, for example, collect data for the twin in a simple, effective way? Within this project, we are also looking at how we can make this accessible to smaller companies." Besides delivering working digital twins, knowledge sharing is a key component of the project.

Predictive maintenance & remote working

Punter sees several reasons for developing digital twins. A digital twin can help to predict problems, test new systems, but can also be used when a machine is already in use: "Imagine a machine producer in the Netherlands that delivers its bread baking machines to Istanbul. Such machines also need support. Thanks to a digital twin, an operator from the company in the Netherlands can see if there are problems in one of their machines, used in Istanbul. You can also start collecting data and recognise patterns in it, in order to predict wear and tear of parts, so that you can replace the right parts in time. AI then helps to find the patterns to do predictive maintenance." The ability to provide remote service can be interesting for both large players and SME organisations. Maintenance can thus be carried out more efficiently and in a better informed manner, but the whole thing is more sustainable because there is less need to travel.

Strengthen Meuse-Rhine Euroregion with the Digital Twin Academy

Educational and industrial partners from the Euregion with South-Limburg and North-Brabant are involved in the project. Together, they want to unlock the technology and share knowledge. Punter: "It's about attracting smaller companies that are not yet able to build digital twins themselves. Interreg sees potential in digital twins for the business community in this Euregion.” That is why cooperation is essential, which is demonstrated by Brainport (North Brabant) and Brightlands (South Limburg). Punter: “For the development of technology and the exploration of its application, it is important nowadays that companies and education cooperate with each other. That is what we are doing in this project. We are carrying out several case studies into the application of digital twins and thus drawing up practical guidelines. We are also organising webinars for educational development and knowledge sessions for businesses. This fits in well with our own working method as Fontys, where we translate practical questions from industry and research directly into education. By learning on the job, you avoid lagging behind."

Broad application of digital twins

As a University of Applied Sciences, Fontys focuses its attention on the practical application of digital twins. Three research groups of its ICT institute are working on this project together with two research groups of Fontys institutes of Engineering and Transport & Logistics (Fontys Venlo). The following test cases have been initiated:

- Smart Industry Twin - a digital twin to connect mobile and robotic arms with an assembly system to show companies the possibilities of smart industry.

- Digital City Twin - a digital twin (in the Eindhoven and Parkstad region) to improve biodiversity in urban environments.

- Robot4Care - a simulation environment has already been developed with the Catharina hospital, which was very useful as a test environment for developers during the pandemic. The digital twin should help showcase the potential of robot-human interaction.

- Virtual Plant Twin - the application of digital twins in horticulture will help to monitor plant growth and predict harvest times.

The largest test case is the Smart Industry Twin. Fontys Engineering has developed a test setup for this, which will be developed into a digital twin together with Fontys ICT. Punter: "We use conveyor belts, which move various objects as in a production process. We think that this set-up is interesting for SMEs as a showcase."

The research project will run until August 2023. The case study implementation and educational development will be carried out in parallel. The project is ambitious, but can have a big impact, says Punter: "It will deliver a lot to SMEs and the region. There will be guidelines for the application of digital twins and clear examples. But also, thanks to this collaboration, research, application and education will come together in a meaningful way."